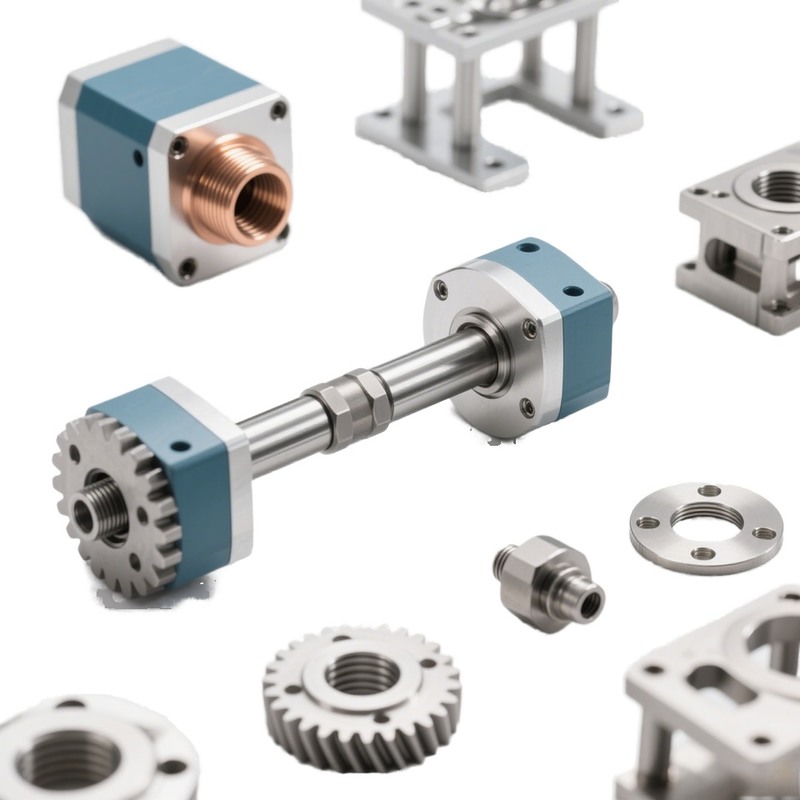

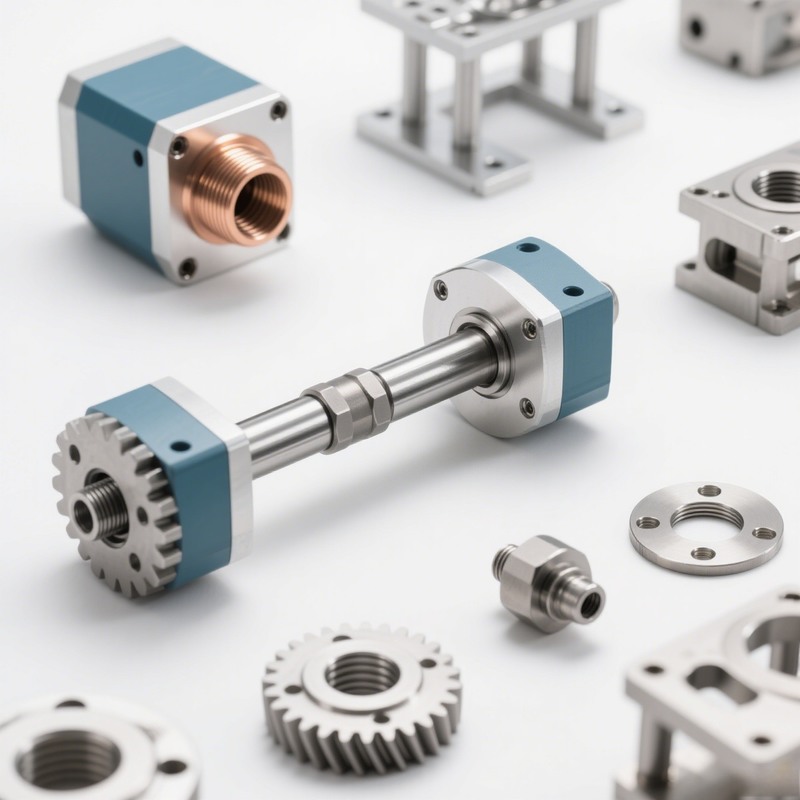

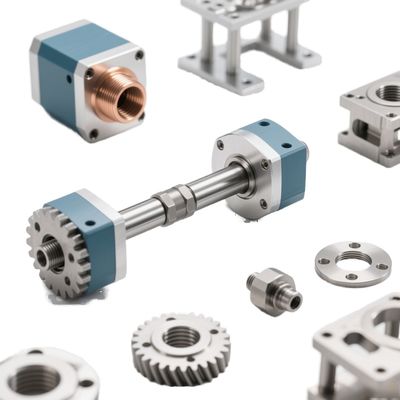

Customized CNC Machining Service for Automotive Parts with Brass Material and Painting Surface Treatment

-

Highlight

Customized CNC Machining Service

,Brass Automotive Parts

,Painting Surface Treatment

-

MaterialSteel, Stainless Steel, Aluminum, Carbon Steel, Mild Steel, Cold Roll, Brass, Copper, Zinc Alloy, Zinc

-

MOQ1000pcs

-

Surface TreatmentPainting, Powder Coating, Plating, Polishing, Brushing, Anodizing, Silkscreen Printing, Sandblast

-

Thickness Range1/32 Inch To 1 Inch

-

Processing MethodsLaser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding

-

Tolerance+/-0.2mm

-

Quality Inspection100% QC With Inspection Form

-

Logo MethodSilk Print, Laser Marking

-

Drawing FormatDWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft

-

Sample Lead Time1-3 Workdays (no Surface Treatment), 3-5 Workdays (with Surface Treatment)

-

PackageBubble Bag, Carton, Wooden Box

-

CNC CapabilityCNC Plasma Cutting Table

-

Assembly CapabilitySpot Welding Into Full Assemblies

-

Color OptionsWhite, Black, Silver, Red, Grey, Pantone, RAL

-

Production Lines4 Production Lines

-

Place of OriginGuangdong, China

-

Brand NameCnc Machining

-

Model NumberOEM

-

Document

-

Minimum Order Quantity1

Customized CNC Machining Service for Automotive Parts with Brass Material and Painting Surface Treatment

OEM Custom CNC Machining Service for Automotive Car Parts

Precision CNC milling and sheet metal fabrication services for aluminum, stainless steel, brass, and other materials.

Sheet Metal Parts and Assembly

Yuanwenyu specializes in sheet metal fabrication for parts and complete assemblies. We work with all metals from 1/32 inch to 1 inch in thickness, producing everything from electronic enclosures to large structural members according to your specifications.

Our CNC Plasma cutting table handles even the most intricate shapes and cutouts. We offer additional services including spot welding assemblies and finishing options like painting, plating, or anodizing.

Send 2D/3D Files for Fast Quote

Custom Precision Sheet Metal Fabrication Specifications

| Material | Stainless Steel, Steel, Aluminum, Carbon steel, Mild steel, Cold roll steel, Brass, Copper, Zinc Alloy, Zinc, etc. |

|---|---|

| Processing | Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding, etc. |

| Surface Treatment | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc. |

| Tolerance | +/-0.2mm, 100% QC quality inspection with quality inspection form |

| Logo | Silk print, Laser marking |

| Color | White, black, silver, red, grey, Pantone and RAL, etc. |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft |

| Sample lead time | No surface treatment: 1-3 workdays. With surface treatment: 3-5 workdays |

| Certificate | ISO9001:2015/SGS/TUV/RoHS |

| Packing | By carton or as per request |

About Us

Huizhou Yuanwenyu Precision Parts Co, Ltd.

With 16 years of experience, we specialize in CNC machining, sheet metal fabrication, and 3D printing services.

- Professional OEM manufacturer with experienced engineers and quality control team

- Commitment to high quality, competitive pricing, and quick response

- Professional technical support and strict quality control processes

- Own assembly workshop with 4 production lines

Manufacturing Technique

Our Advantages

- All parts are deburred with dimensions strictly controlled to your drawings

- Rigorous craftsmanship with process cards and charts for every product

- Strict quality inspection procedures including self-inspection, flow inspection, and professional inspection

- 100% size testing after production with quality reports

- Direct factory (not trading company) offering better quality control and competitive pricing

- Extensive export experience to US, Europe, Japan and other regions

- Professional team with multilingual capabilities

Buyer Reviews

Packaging & Transportation

Frequently Asked Questions

Q1: How long can I get the sample?

3-5 days for samples, 10-15 days for bulk orders. We can expedite based on your specific requirements.

Q2: How do you control product quality?

Our process includes full size inspection, mass production monitoring, 3-hour sampling checks, and 100% shipping random checks. We have a professional QC team overseeing all stages.

Q3: What information do you need for a quote?

Please provide product drawings in PDF format. DWG or STEP formats are preferred for more accurate quotes.

Q4: Do you offer OEM/ODM services with custom logos?

Yes, we welcome OEM/ODM projects and can apply customer logos to products.

Q5: What are your payment terms?

Standard terms are 30%-50% deposit with 50%-70% balance via T/T, Western Union, or PayPal. Other arrangements can be discussed based on our cooperation.

Q6: Can you handle shipping if we don't have a forwarder in China?

Yes, we can recommend optimal shipping solutions to ensure timely delivery at competitive prices.

Q7: Can you assist with travel arrangements for visiting China?

We're happy to provide one-stop services including ticket booking, airport pickup, hotel reservations, and accompanying you to markets or factories.