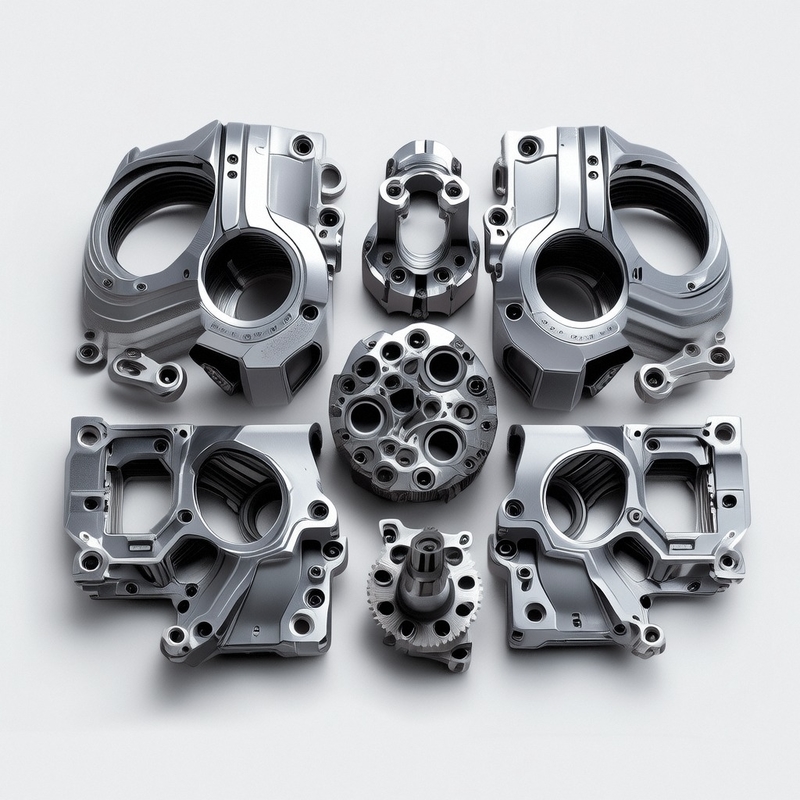

Precision CNC Milling Parts Stainless Steel 304 with 100% QC Inspection

-

Highlight

Precision CNC Milling Parts Stainless Steel

,CNC Milling Parts with QC Inspection

,Stainless Steel 304 CNC Milling Parts

-

Machining TypeBroaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

-

Material CapabilitiesAluminum, Brass, Bronze, Copper, Hardened Metals, Other, Precious Metals, Stainless Steel, Steel Alloys

-

Micro MachiningYes

-

Surface TreatmentSandblasting, Anodizing, Powder Coating

-

Drawing FormatDXF / DWG / STEP / IGS / PDF

-

Stainless Steel GradesSS201, SS301, SS303, SS304, SS316, SS416

-

Steel GradesMild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#

-

Brass GradesHPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90

-

Copper GradesC11000, C12000, C12000, C36000

-

Aluminum GradesAL6061, Al6063, AL6082, AL7075, AL5052, A380

-

Iron GradesA36, 45#, 1213, 12L14, 1215

-

Plastic TypesABS, PC, PE, POM, Nylon, PP, Peek

-

CNC Machines25 Sets CNC Machining Centers, 12 Sets CNC Turning And Milling Compound Machining Centers, 20 Sets CNC Lathes

-

3D Printing Equipment10 Sets

-

Inspection EquipmentTwo-dimensional, Three-dimensional Testing Equipment

-

Place of OriginGuangdong, China

-

Brand NameYWY

-

Model NumberYWY442, OEM

-

Document

-

Minimum Order Quantity1

Precision CNC Milling Parts Stainless Steel 304 with 100% QC Inspection

CNC Manufacturing for Electrical Parts Stainless Steel Prototype and Milling Parts Wire EDM Technology

Product Specifications

| Attribute | Value |

|---|---|

| CNC Machining or Not | CNC Machining |

| Type | Broaching, Drilling, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Other, Precious Metals, Stainless Steel, Steel Alloys |

| Micro Machining | Micro Machining Available |

| MOQ | Small orders accepted |

| Cost Control | Most efficient production process design |

| QC Control | 100% inspection on critical dimensions |

| Management | Skilled workers and experienced staff |

| Surface Treatment | Sandblasting, Anodizing, Powder Coating |

| Drawing Format | DXF/DWG/STEP/IGS/PDF |

| Quality Control | 100% Guaranteed |

Product Overview

The products shown here represent the scope of our business activities. We specialize in CNC milling, turning, lathe work, wire cutting, and EDM - all performed in-house at our factory in Huizhou, Guangdong, China.

Contact us for a free quote - no minimum order quantity required. We can also add your logo or design to products using our laser marking machine.

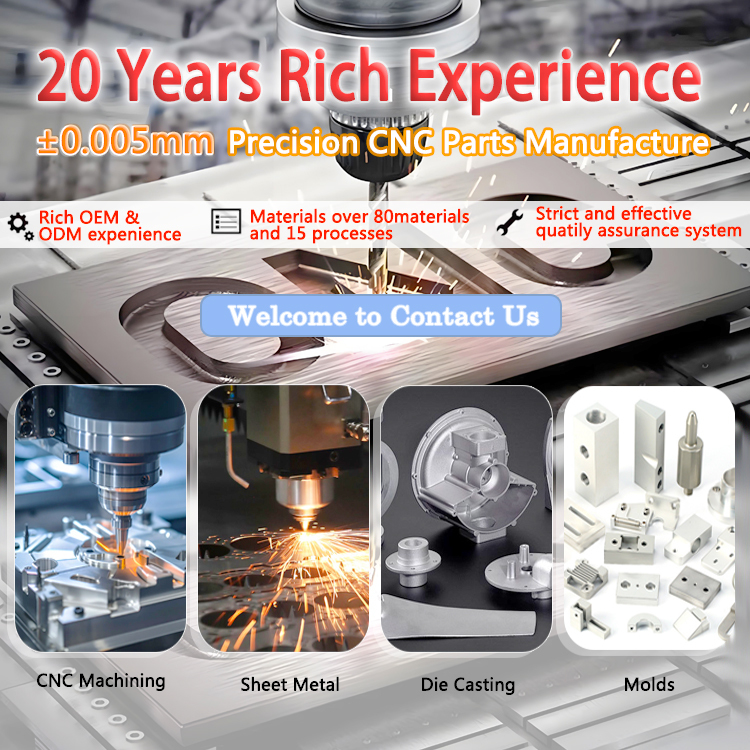

CNC Machining Services

Our CNC precision hardware serves diverse industries including aerospace, automotive, medical, and defense. We collaborate closely with clients to develop customized solutions, whether for single prototypes or high-volume production.

3D Printing Services

Our 3D printing capabilities support industries from aerospace to medical devices, offering materials including plastics, metals, and carbon fiber for exceptional strength and precision.

Material Options

| Material Type | Available Grades |

|---|---|

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416 |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 |

| Copper | C11000, C12000, C12000, C36000 |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 |

| Iron | A36, 45#, 1213, 12L14, 1215 |

| Plastic | ABS, PC, PE, POM, Nylon, PP, Peek |

Surface Treatment Options

| Material | Available Treatments |

|---|---|

| Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated |

| Aluminum | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing |

| Plastic | Plating gold (ABS), Painting, Brushing (Acylic), Laser engraving |

Technical Support

Our engineers are proficient in AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D software. We can design, develop, produce and deliver according to your drawings, samples, or ideas.

Quality Control Process

- Incoming quality control (IQC) - Raw material inspection

- Pre-production verification

- In-process quality control (IPQC) - Full inspection during production

- Final quality control (FQC) - Post-production verification

- Outgoing quality control (OQC) - Pre-shipment inspection

Company Profile

Huizhou Yuanwenyu Precision Parts Co., Ltd. has 16 years of manufacturing experience specializing in CNC processing, CNC lathe processing, sheet metal processing, 3D printing, and custom design services.

We support customization of various precision parts in metal (aluminum, copper, titanium alloy) and plastic (ABS, PP, Teflon, carbon fiber), with post-processing options including plating, anodizing, and polishing.

Our facility includes:

- 25 CNC machining centers

- 12 CNC turning and milling compound machining centers

- 20 CNC lathes

- 10 3D printing equipment

- Wire cutting, grinding machines, and stamping equipment

- 2D/3D testing equipment

Why Choose Us

- Design assistance and full engineering support

- OEM CNC parts specialization

- Complete production lines for custom machining and fabrication

- Advanced machine tools and CAD/CAM programming

- Prototype machining capabilities

- Strict quality control standards

- Continuous equipment upgrades

- Small quantity orders accepted

Frequently Asked Questions

Are you a manufacturer or trading company?

We operate a 1500-square-meter factory in Huizhou, China.

Can I get a quote without drawings?

Yes, we can quote based on samples, pictures, or drafts with dimensions.

How do you protect my design confidentiality?

We strictly protect customer privacy and can sign NDAs if required.

What is your typical lead time?

1-2 weeks for samples, 3-4 weeks for production.

What if I receive defective parts?

Send photos and we will immediately analyze and remake the parts.