-

Highlight

EDM Custom Plastic Injection Molding

,Texturing Custom Plastic Injection Molding

-

SizeMax. Mold Size: 1500 X 1200mm

-

MaterialABS, PC, PP, PA, POM, Etc.

-

ProcessInjection Molding, Overmolding, Insert Molding, Etc.

-

Mold BaseLKM, HASCO, DME, Etc.

-

Lead Time3-4 Weeks

-

Tolerance±0.05mm

-

CavitySingle Or Multi-Cavity

-

Mold Life500,000-1,000,000 Shots

-

Place of Originguangdonghuizhou

-

Brand Nameywy

-

Model Numberywy123

-

Document

-

Minimum Order Quantity1 Perch/Perches

-

PriceUSD 3.88-32.88 1 Perch/Perches

-

Packaging DetailsCarton packaging and blister box

-

Delivery Time10-15work days

-

Payment TermsL/C D/A D/P T/T Western Union MoneyGram

-

Supply Ability1000 Perch/Perches 10-15work days

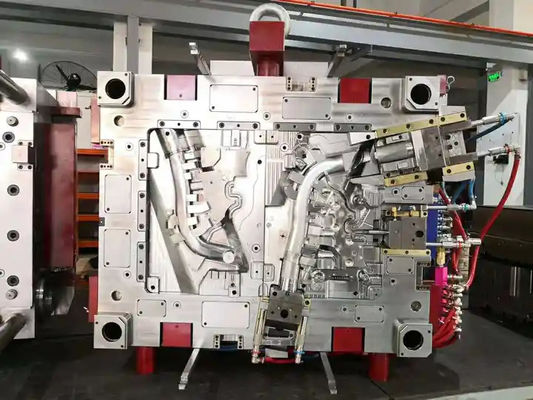

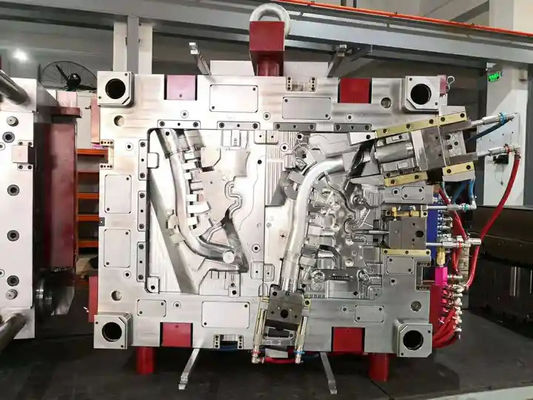

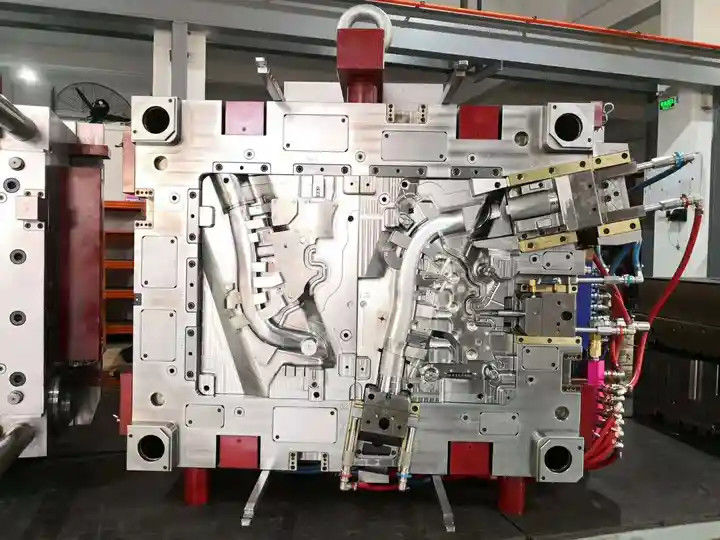

EDM Custom Plastic Injection Molding Texturing Surface Finish

Product Description:

Injection Molding Services provide excellent molding services for customers. With a maximum mold size of 1500 X 1200mm, our injection molding services are able to handle the requirements of customers. Our injection molding process starts with injection molding, overmolding, insert molding, and other processes. In addition, our molding process is able to achieve high precision with a tolerance of ±0.05mm. We also have advanced equipment such as CNC, EDM, Wire-Cutting, and more. All of these technologies and processes combined ensure that our injection molding services are of the highest quality.

Our injection plastic molding service involves the use of high-grade materials that can be used in a variety of applications. We have a team of experienced professionals who have expertise in injection service molding. Our injection molding services also have a great deal of experience in overmolding and insert molding, which helps us provide a wide range of injection molding services.

We are proud to offer our customers the highest quality injection molding services. Our injection molding process is reliable and precise, with a tolerance of ±0.05mm. We also have advanced equipment such as CNC, EDM, Wire-Cutting, and more, which helps us provide a wide range of injection molding services. Our injection plastic molding service also involves the use of high-grade materials that can be used in a variety of applications.

Features:

- Product Name: Injection Molding Services

- Material: ABS, PC, PP, PA, POM, Etc.

- Equipment: CNC, EDM, Wire-Cutting, Etc.

- Lead Time: 3-4 Weeks

- Service Type: Molding Injection Service, Plastic Injection Molding, Plastic Injection Molding Services

- Software: UG, Pro/E, SolidWorks, Etc.

Technical Parameters:

| Parameters | Details |

|---|---|

| Software | UG, Pro/E, SolidWorks, Etc. |

| Surface Finish | Polishing, Texturing, Painting, Etc. |

| Lead Time | 3-4 Weeks |

| Mold Life | 500,000-1,000,000 Shots |

| Mold Base | LKM, HASCO, DME, Etc. |

| Process | Injection Molding, Overmolding, Insert Molding, Etc. |

| Cavity | Single Or Multi-Cavity |

| Weight | Max. Mold Weight: 10,000kg |

| Material | ABS, PC, PP, PA, POM, Etc. |

| Service Type | Injection Molding Services |

Applications:

YWY brand’s Injection Molding Services provide an efficient and cost-effective process for producing high-quality plastic parts in a variety of shapes and sizes, with a model number of ywy333, and the origin of Guangdonghuizhou. The maximum mold size of this injection molding service can reach 1500 X 1200mm, with a maximum mold weight of 10,000kg. The mold life can be up to 500,000 to 1,000,000 shots. The materials of this injection molding service includes ABS, PC, PP, PA, POM, etc.

The Molding Injection Service offers a variety of advantages, including a high degree of accuracy, repeatability, and cost savings. It is a perfect solution for any plastic injection molding process. It is widely used in various industries, such as automotive, medical, electronics, consumer goods, and many more. It is also used for prototyping, small-scale production, and large-scale production. The Process Injection Molding is a fast and efficient way to produce quality plastic parts. It has high accuracy, repeatability, and cost-effectiveness. The Injection Plastic Molding is a great way to produce high-quality plastic parts quickly and cost-effectively.

Customization:

YWY is your one-stop source for injection molding services. Our injection molding services include injection molding, overmolding, insert molding, and more, using various materials such as ABS, PC, PP, PA, POM, and more.

- Brand Name: YWY

- Model Number: YWY333

- Place of Origin: Guangdong, Huizhou

- Equipment: CNC, EDM, Wire-Cutting, etc.

- Process: Injection Molding, Overmolding, Insert Molding, etc.

- Material: ABS, PC, PP, PA, POM, etc.

- Software: UG, Pro/E, SolidWorks, etc.

- Lead Time: 3-4 weeks

Our experienced team of engineers and designers use the latest software and technologies to provide superior product quality, accuracy, and speed. We specialize in plastic injection molding services, and have the experience and expertise to provide high-quality, cost-effective solutions.

Support and Services:

Injection Molding Services Technical Support and Services

We provide technical support and services for our Injection Molding Services. Our team of experienced engineers and technicians can help you with the design, development, and manufacturing of your injection-molded parts. We also provide troubleshooting and repair services to ensure the highest quality product.

We use advanced engineering software to assist in the design process and can provide detailed design drawings. We also have a variety of rapid prototyping services to help you quickly and cost-effectively develop your injection-molded part.

In addition, our team can provide valuable insight into the injection molding process, helping you develop and manufacture your part accurately and efficiently. We also use advanced quality control techniques to ensure that your part meets your exact specifications.