-

Highlight

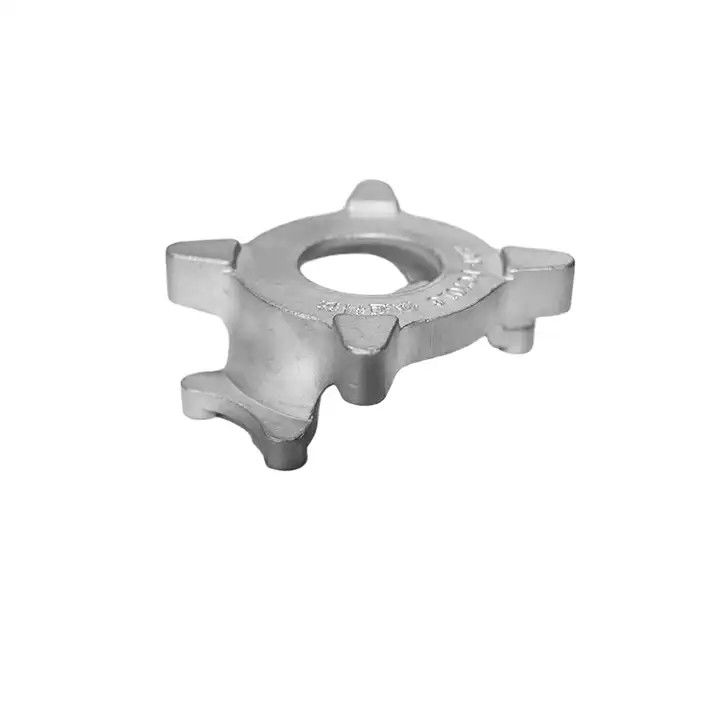

Aluminum Die Casting Components

,Zinc Die Casting Components

-

Tolerance±0.01mm

-

Weight0.1-50kg

-

ApplicationAutomotive, Electronics, Industrial, Etc.

-

PackageWooden Case/Pallet

-

Surface FinishPolishing, Anodizing, Plating, Painting, Etc.

-

ShippingBy Sea/Air/Express

-

MaterialAluminum, Zinc, Magnesium, Copper, Etc.

-

Mold Life50,000-1,000,000 Shots

-

Place of Originguangdonghuizhou

-

Brand Nameywy

-

Model Numberywy123

-

Document

-

Minimum Order Quantity1 Perch/Perches

-

PriceUSD 3.88-32.88 1 Perch/Perches

-

Packaging DetailsCarton packaging and blister box

-

Delivery Time10-15work days

-

Payment TermsL/C D/A D/P T/T Western Union MoneyGram

-

Supply Ability1000 Perch/Perches 10-15work days

Aluminum Zinc Die Casting Components

Product Description:

Die Castings Components are precision aluminum alloy castings produced using gravity casting, sand casting, and low pressure die casting processes. The components are highly customizable in terms of size, pressure, and surface finish, with polishing, anodizing, plating, and painting options available.The components are packaged and shipped according to customer needs, including by sea, air, and express delivery options. Aluminum alloy castings produced by die casting are highly durable, offering a maximum pressure of 500T.

Features:

- Product Name: Die Casting Components

- Package: Wooden Case/Pallet

- Lead Time: 7-15 Days

- Size: Customized

- Tolerance: ±0.01mm

- Weight: 0.1-50kg

- Lost Wax Castings

- Sand Castings

- High-pressure Die Castings

- Aluminum Alloy Die Casting

- Zinc Alloy Die Casting

Technical Parameters:

| Parameter | Description |

|---|---|

| Size | Customized |

| Weight | 0.1-50kg |

| Application | Automotive, Electronics, Industrial, Etc. |

| Lead Time | 7-15 Days |

| Surface Finish | Polishing, Anodizing, Plating, Painting, Etc. |

| Shipping | By Sea/Air/Express |

| Processing | Die Casting, CNC Machining, Etc. |

| Mold Life | 50,000-1,000,000 Shots |

| Tolerance | ±0.01mm |

| Design | 3D/2D Drawing |

| Highlighted | Die Casting Molds, Aluminum Alloy Castings, Sand Castings, Investment Castings |

Applications:

YWY brand die casting components are widely used in various application scenes, such as automotive, electronics, industrial, etc. Our die casting components are made of high-quality materials, such as lost wax castings, die casting molds and magnesium alloy castings. With YWY444 model, we offer efficient and reliable casting services with fast lead time of 7-15 days. The mold life of our die casting components can last from 50,000 to 1,000,000 shots, and the maximum pressure can reach up to 500T. We also provide reliable packaging service, such as wooden case and pallet.

Customization:

Brand Name: ywy

Model Number: ywy444

Place of Origin: guangdonghuizhou

Tolerance: ±0.01mm

Processing: Die Casting, CNC Machining, Etc.

Material: Aluminum, Zinc, Magnesium, Copper, Etc.

Application: Automotive, Electronics, Industrial, Etc.

Mold Life: 50,000-1,000,000 Shots

We provide comprehensive and customized services for Die Casting Components, including Metal Injection Moldings, Aluminum Alloy Castings, Die Castings, CNC Machined Parts, etc. Our strict tolerance control (±0.01mm) allows us to manufacture high-quality components with various materials (Aluminum, Zinc, Magnesium, Copper, etc.) for customers in various industries (Automotive, Electronics, Industrial, etc.), with a mold life of 50,000-1,000,000 shots.

Support and Services:

We provide comprehensive technical support and services for die casting components. We can help you to select the suitable die casting process, materials, and molding tools. Our experienced staff will work with you to ensure that the components are designed to your specifications and tolerances. Furthermore, we have a wide network of die casting partners to meet the needs of any production scale.

We have the capability to provide on-site die casting services, from small components to high volume parts. Our team of engineers and technicians have the expertise to ensure that the components are manufactured to the highest quality standards. We use state-of-the-art equipment and technologies to streamline the die casting process.

We also offer after-sales services and maintenance. Our team will work with you to maintain the quality of your die casting components and keep them in optimal condition. We can also provide spare parts and maintenance services to ensure that the components are running smoothly.

If you have any questions about our technical support and services for die casting components, please do not hesitate to contact us.