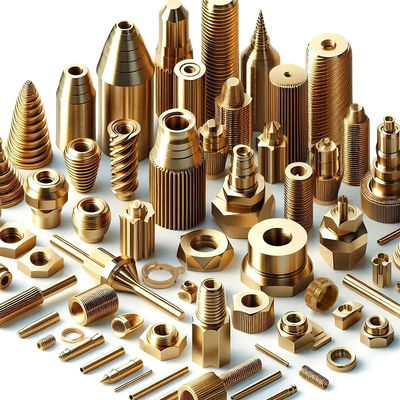

CNC Turning Milling Parts are precision-made components that are used in various industries such as automotive, aerospace, medical, and electronics. They are essential in the production of high-quality and complex products, making them a crucial part of the manufacturing process.

Our CNC Turning Milling Parts come with various surface treatment options to provide the desired finish and protection:

We have a minimum order quantity of 1 piece for our CNC Turning Milling Parts, making it easier for our clients to order even small quantities. We also guarantee a tolerance of ±0.01mm to ensure the highest level of accuracy and consistency in our products.

With our advanced CNC Milling Manufacturing Parts, CNC Milling Manufactured Parts, and CNC Milling Machine Parts, we strive to provide high-quality and customized solutions to our clients. Our focus on precision, fast delivery, and flexibility makes us a reliable partner for all your CNC Turning Milling Parts needs. Contact us today to learn more about our services and request a quote!

| Product Name | CNC Turning Milling Parts |

|---|---|

| Advantage | High Precision, Fast Delivery, Etc. |

| MOQ | 1 Piece |

| Package | Carton, Wooden Case, Etc. |

| Product Size | Customized |

| Surface Treatment | Polishing, Anodizing, Zinc Plating, Etc. |

| Processing Method | CNC Turning Milling |

| Tolerance | ±0.01mm |

| Drawing Format | PDF, IGS, STP, DWG, Etc. |

| Material | Stainless Steel, Aluminum, Brass, Etc. |

| Shipping | Express, Air, Sea |

Brand Name: ywy

Model Number: cnc202

Place of Origin: guangdonghuizhou

Minimum Order Quantity: 1

Price Range: $0.68 - $6.68

Packaging Details: Bubble paper box packaging

Delivery Time: 10-15 days

Supply Ability: long-term

Lead Time: 7-15 days

Surface Treatment: Polishing, Anodizing, Zinc Plating, Etc.

Application: Automotive, Aerospace, Etc.

Product Size: Customized

Drawing Format: PDF, IGS, STP, DWG, Etc.

CNC Turning Milling Parts, also known as CNC Milling Machining Parts, are highly advanced and precise parts that are widely used in various industries such as automotive and aerospace. These parts are manufactured using cutting-edge CNC milling machines, which allow for high precision and accuracy in the production process.

CNC Turning Milling Parts have a wide range of applications and are used in various industries such as automotive, aerospace, electronics, and more. These parts are used in the manufacturing of components for machines, equipment, and tools. They are also used in the production of prototypes and small batches of products.

The production process of CNC Turning Milling Parts involves several steps, including designing, programming, machining, surface treatment, and quality control. The process begins with the design of the part using specialized CAD software. The design is then converted into a program that can be read by the CNC milling machine. The machine then cuts and shapes the raw material according to the programmed design. After the machining process, the parts are treated with different surface treatments, such as polishing, anodizing, or zinc plating, to enhance their appearance and functionality. Finally, the parts go through a rigorous quality control process to ensure they meet the required specifications and standards.

CNC Turning Milling Parts, manufactured by ywy, are high-quality and precise parts that are widely used in various industries. These parts are customizable, durable, and efficient, making them a preferred choice for many businesses. With advanced technology and a skilled team, ywy is committed to providing high-quality CNC milling manufacturing parts to meet the diverse needs of its customers.

Order your CNC Turning Milling Parts today and experience the superior quality and precision of ywy's products!

Brand Name: YWY

Model Number: CNC202

Place of Origin: Guangdong Huizhou

Minimum Order Quantity: 1

Price: $0.68-$6.68

Packaging Details: Bubble paper box packaging

Delivery Time: 10-15 days

Supply Ability: Long-term

Shipping: Express, Air, Sea

OEM/ODM: Accept

Application: Automotive, Aerospace, etc.

Material: Stainless Steel, Aluminum, Brass, etc.

Lead Time: 7-15 days

At YWY, we offer customized CNC turning milling parts to meet your specific needs. Our CNC milling process parts are fabricated with precision and accuracy, ensuring high quality and reliable performance. Our CNC milling machining parts are suitable for various applications, such as automotive and aerospace industries.

Our CNC turning milling parts are carefully packaged to ensure safe transportation and delivery to our customers. The packaging process includes the following steps:

Once the packaging process is complete, the parts are ready for shipping. We offer various shipping options to meet our customers' needs, including:

Our team carefully tracks each shipment to ensure timely delivery and provides our customers with tracking information so they can monitor their package's progress. We also offer insurance options for added protection during transit.

At CNC Turning Milling Parts, we are committed to providing our customers with high-quality parts and reliable shipping services. Contact us today to learn more about our packaging and shipping options.